Carbon Fiber Luggage

Carbon Fiber Luggage

Product Details

Description: Carbon Fiber Luggage

Material: Carbon Fiber

Features: Carbon Fiber Luggage offers exceptional strength-to-weight ratio, being 4-5 times stronger than steel yet significantly lighter than aluminum alloys. Its corrosion-resistant properties ensure durability in harsh environments, while advanced impact resistance protects contents during transit. The sleek, woven carbon fiber exterior delivers a premium, high-tech aesthetic ideal for luxury travel.

Available Public mold: 20-inch Carbon Fiber Luggage available in public mold designs – Ready for immediate OEM branding with no mold costs. TSA-approved, ultra-lightweight, and fully compliant with IATA carry-on size standards.

More Details:

Crafted from aerospace-grade carbon fiber composites, these suitcases combine a 1.7 g/cm³ ultra-light density with unmatched structural integrity. The material’s fatigue resistance ensures the long time lifespan, outperforming traditional luggage under repeated stress. Proprietary lamination techniques enhance thermal stability and dimensional consistency across climates. For clients, customization includes TSA-approved locks, modular interiors, and scalable production via automated thermoplastic molding for high-volume orders. Elevate your brand with this fusion of elite engineering and luxury design.

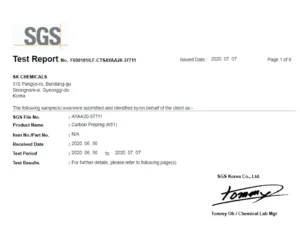

SGS certificate

1. Q: What makes carbon fiber luggage superior to traditional materials like aluminum or polycarbonate?

A: Carbon fiber luggage offers an exceptional strength-to-weight ratio – 5x stronger than steel yet 40% lighter than aluminum alloys. Its corrosion resistance ensures longevity in humid environments, while low thermal expansion maintains structural integrity across temperature extremes.

2.Q: Can you customize luggage dimensions/designs for specific client needs?

A: Yes. We support full OEM/ODM customization via:

-3D modeling integration (IGS/STP files)

-Modular interior layouts for tech segments

-Brand-specific colors, weaves, and laser-etched logos

-TSA-approved lock integration and reinforced corners

3. Q: What manufacturing processes ensure quality consistency?

A: We use aerospace-grade prepreg carbon fiber with:

Automated thermoplastic molding for batch uniformity

Vacuum bagging + RTM (Resin Transfer Molding) eliminating voids

3-layer impact dispersion at stress points

4. Q: What carbon fiber grades (e.g., T300, T700, T800) are optimal for different luggage applications?

A: T700 (Standard): Ideal for mainstream business luggage (1,500+ MPa tensile strength).

T800 (Premium): Recommended for luxury/executive lines (2,000+ MPa strength).

T300 (Economy): Suits budget-conscious corporate gifts (1,200 MPa strength).

✈️ 1. Frequent Flyer Executives

For corporate travelers maximizing airline weight limits.

Carbon fiber luggage reduces baggage weight by 30–40% vs. aluminum, enabling compliance with strict airline policies (e.g., 7kg carry-on limits). Its crush resistance protects sensitive documents and electronics during rough handling.

💼 2. Luxury Retail & Corporate Gifting

High-end branding for premium client experiences.

Customizable 6K twill weave exteriors with laser-etched logos convey exclusivity. The material’s aerospace heritage aligns with luxury positioning, while scratch-resistant surfaces maintain pristine appearance after repeated use.