Service

Service

What We Do

Foni offers comprehensive services for manufacturing custom-shaped carbon fiber parts from initial prototyping to mass production. Our well-established production process includes cutting, molding, trimming & bonding, grinding, polishing, painting, and printing. Furthermore,we specialize in our core manufacturing technologies: compression molding, RTM (Resin Transfer Molding), and autoclave molding.

Below is a detailed breakdown of our end-to-end service flow:

1. Enquiry

Clients send the enquiry details to us according to their spec request.

2. R&D Analysis and Evaluation

We will sigh a confidentiality agreement for customized products to protect the client’s proprietary design information.Our R&D team will analyze and assess the feasibility of ideas and design request.

3. Material Selection

When selecting the carbon material for product development, the primary considerations include material type, performance requirements(strength,stiffness,thermal stability), and application-specific factors.

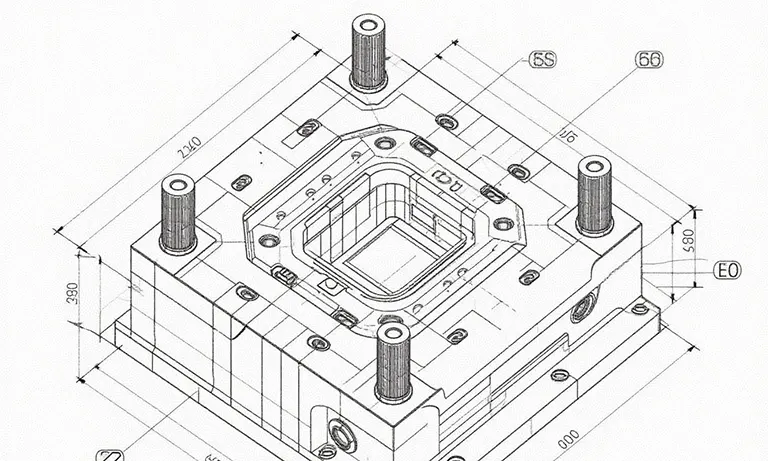

4. Mold Design and Making

Refers to the creation of molds for product production, a critical step in manufacturing workflows .

5. Sample Production

Involves creating prototypes or samples to test design and functionality, as highlighted in product development processes and manufacturing documentation.

6. Testing

Includes the validation stage to ensure product quality, which could meet the clients’ request standard.

7. Mass Production

For production, we could do small runs and big runs-whatever fit your needs. We’ve got full production lines running in our facility, and we keep close eyes on every single step to make sure quality is spot-on.

8. Quality Inspection

Final checks to ensure products meet standards, and make sure that the bulk goods quality is perfect.

9. Packing & Shipping

We execute fully customized packaging per your specifications — from branded boxes to protective materials — ensuring premium presentation and transit safety. Standard shipping terms are EXW or FOB, we are open for any discussion if clients have special request.

The Latest in Carbon Fiber News

Cutting-Edge Innovations, Breakthroughs & Industry Trends

Choosing the Right Carbon Fiber Hydrofoil for Your Water Sports Application

The world of water sports is evolving, and carbon fiber hydrofoils are at the forefront of this revolution. Whether you're a retailer, distributor, or water sports business looking to stock high performance hydrofoils, choosing the right configuration is critical to meet the needs of your customers.